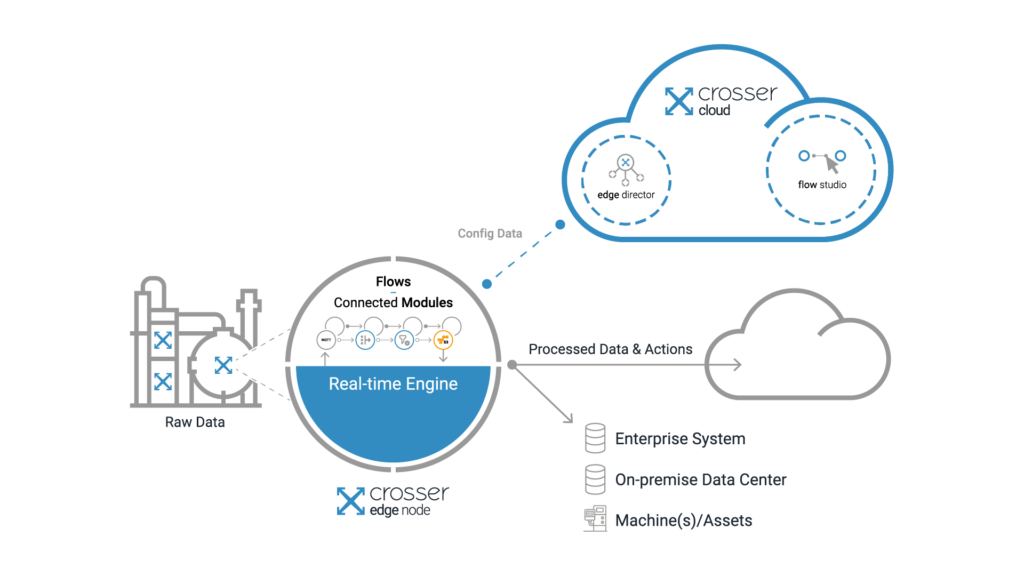

The Crosser Platform enables real-time processing of streaming or batch data for Industrial IoT, Data Transformation, Analytics, Automation, and Integration.

The solution is built to fight complexity with simplicity through the Crosser Flow Studio, the visual design tool that enables teams to innovate faster than ever without developers. The software is ideally suited for Enterprise customers of various industries and applications, including Edge Analytics, Industrial Connectivity, Industry 4.0, Streaming Analytics, Hybrid Integration and Intelligent Workflows.

For more information, please click here.

Industry, Applications & Use Cases

Discover how you can benefit from our partnership by viewing below qualified projects or get in touch with us directly

Description

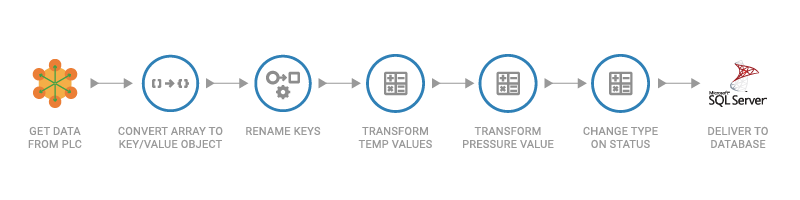

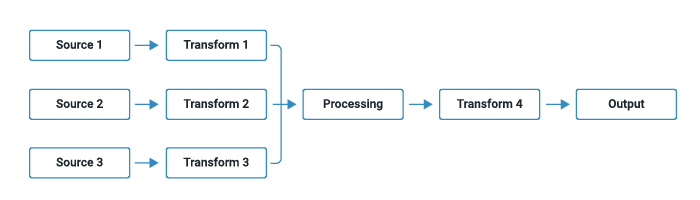

Transformation and Harmonization are closely related, the only difference being that with harmonization we are dealing with multiple sources and need to apply different transformations to each of them with the goal to convert them into a common format and/or structure.

When harmonizing time series data from multiple sources there might be an additional issue that must be dealt with data from different sources arriving at different times or with different sample rates.

The Challenge

A common problem in our industry is data mismatch, we want to use data from different sources, but they deliver different formats, or we have data in one format and want to send it to another system that expects data in another format.

The Solution

Data harmonization comes into play when we have multiple sources with different formats, and we want to combine the data so that we can treat the data in the same way independent of the original source. To harmonize the data, we typically apply different transformations to each of the sources to produce a common format.

Depending on the requirements of the processing and/or receiving system we might have to align data on common time steps. This can be done by shifting the data, if the sampling rate is the same, or by interpolating/aggregating data if different sampling rates are used.

This is especially important if the data will be used with machine learning models, since these expect each new sample to contain data from each of the sources the model was trained on.

Why Crosser

Crosser provides a low code platform for helping asset rich enterprises make their data useful. Get insights to optimize operations and take appropriate actions immediately based on the enterprise data.

Other transformations such as removing outliers/noise and changing resolution (aggregation/filtering) can easily be added to any type of data flow using standard modules from the Crosser library. Read more.

Why Moxa

Moxa provides the computing hardware platform for the Crosser solution and can extend and secure the reach of the local Crosser gateway with their networking, security and connectivity portfolio.

Description

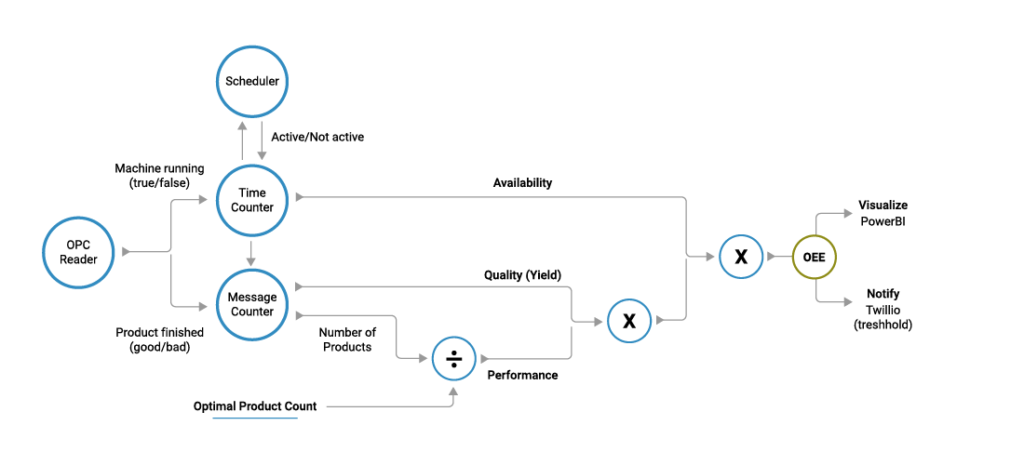

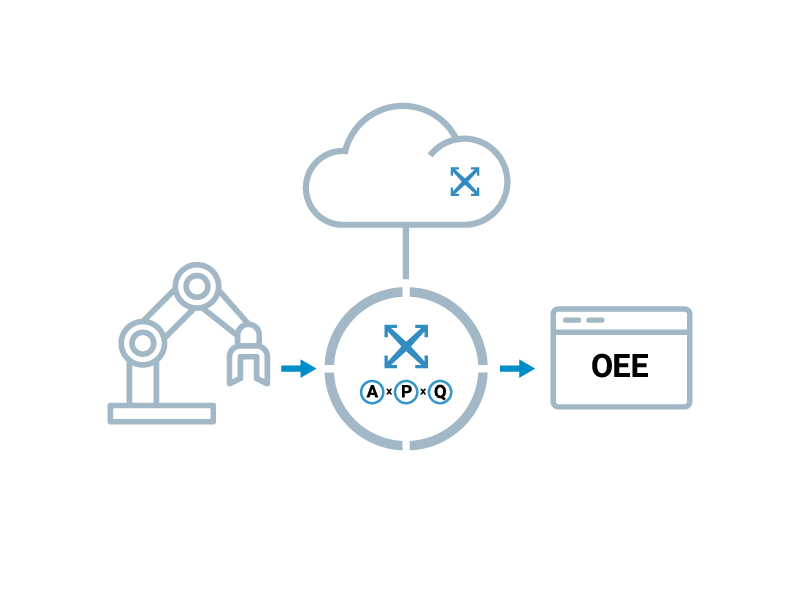

An important use of machine data is to calculate different KPIs to measure the performance and behavior of machines or processes. Actions can be taken directly from the edge processing, while the actual KPI values can be delivered to on-premise or cloud systems for direct visualization and/or storage for trend analysis. If actions need to be taken based on trend analysis the edge can be complemented with a time series database to allow local analysis that also uses historical data.

The Challenge

The demand for big data analytics is huge within the global industries, for understanding processes and optimizing production. Typically, the OEE for the overall process is set for many years using third party services and systems. But when enterprises want to become fully digital, the need for additional KPI’s is increasing. This is a very challenging task, especially when managing production sites on a global market.

Streamlining data, comparing different machines and production lines and sites, demands a very simple way of developing, deploying and maintaining the KPI data flows. Clearly for reducing cost, but also for faster implementation. This is why Crosser Low Code Platform really comes into play.

The Solution

The Crosser Edge Streaming Analytics solution is the perfect platform for performing KPI calculations and data integration. For both Industrial Edge use cases and on-premise or cloud KPI calculations.

Crosser provides a low code studio for simplifying KPI development, testing and deployment. But also, a real-time runtime where industries can execute their KPI data flows. This runtime can be managed remotely and be installed at the edge, on-premise or in the cloud – depending on the designated use case.

Why Crosser

The Crosser module library has a set of functional modules specifically targeting KPI calculations. Combined with more than 700 connector modules to collect data from machines, and other assets, and deliver results to different on-premise and cloud systems, a complete KPI driven analytics pipeline can easily be implemented. Read more.

Why Moxa

Moxa’s portfolio for embedded computers can support a variety of connectivity as well as performance and storage requirements to serve both simple cost-effective use cases as well as more complex and demanding scenarios.

Description

Extracting valuable insights out of data collected from machine sensors can be hard, often requiring analyzing data from many sensors in parallel.

Due to the complexity, machine learning (ML) methods are becoming more and more popular to enable for example prescriptive maintenance, improved user experiences, and predictive maintenance programs.

The Challenge

Applying machine learning models in industrial environments comes with several challenges, besides obvious concerns like security and data availability, machine learning projects often face challenges with data formats, sample rates, network accessibility and such for implementing the models. It is very common that operators have to be on site for installing the models, which makes global scaling very time consuming and expensive.

The Solution

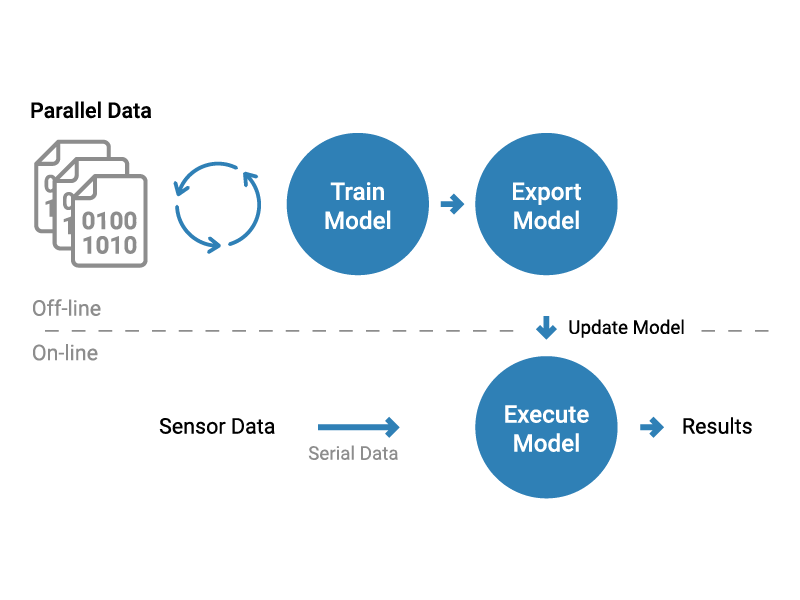

The Crosser Edge Analytics Platform is built for simplifying every step of the Industrial Machine Learning Project. From:

- Retrieving data and preparing it for the designated model.

- Distributing and updating machine learning models at scale.

- Running the inference of live data in real-time.

- Integrating the real-time data stream to needed systems and services.

Why Crosser

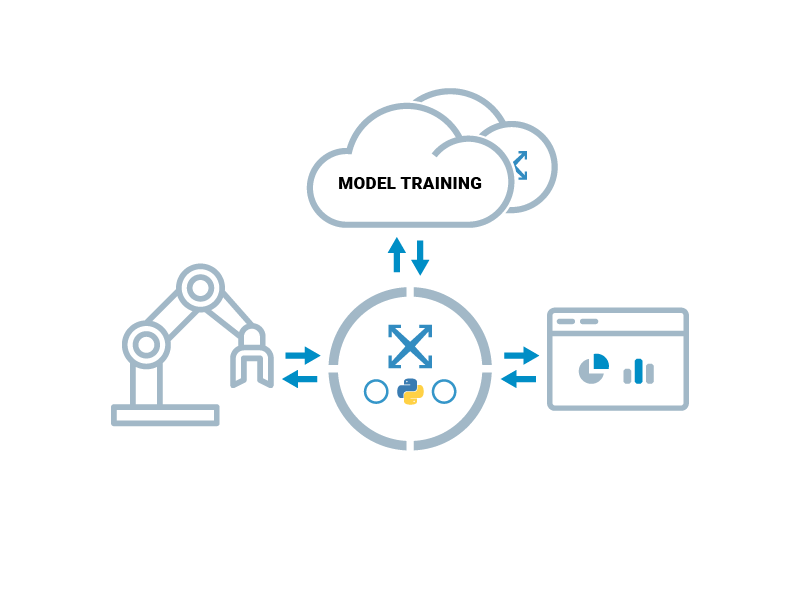

To make sure we can host your ML model independent of the choices made by your data science team Crosser has decided to introduce the “Bring Your Own AI” concept.

In the Crosser Edge node, you have access to a standard Python environment. This environment is configured through a standard flow module, where you setup the libraries needed and the code you want to run. In this way you can be sure your model can run in the correct environment, as expected by your model developers. Read more

Why Moxa

Moxa’s computer portfolio scales from small ARM-based IIoT gateways to Intel Atom or Core i-based edge computers. Alongside the overall Moxa portfolio, they serve as the hardware part of a company’s Industrial IoT infrastructure. Together with the Crosser platform customers can build their own stable and reliable hardware and software platform for their continuously improving data and analytics applications that are naturally moving more and more from the cloud to the edge.

Description

Modern data centers, buildings and industrial production sites have one thing in common: they consume a lot of electricity. Climate change, environmental considerations, and plain economic pressure mandate that the consumption of electricity is carefully tracked and minimized as much as possible. So renewable energy sources, grid power and storage system as well as big power consumers need to be monitored

The Challenge

Getting relevant data continually is a challenge due to the multitude of data sources, incomplete data, lack of metadata, inconsistent time stamping and more. And both the data sources on site as well as the data requirements in the cloud are subject to change over time.

The Solution

Crosser’s cloud platform and software at the edge offers rich connectivity both locally and to IT/cloud systems, data processing capabilities and the tools to make the solution scale over many locations as well as to varying requirements over time – without the need for on-site visits and without programming.

Why Crosser

There are pre-built modules within the Crosser Module library for normalizing and transforming data to enhance data quality for future processing and storage. Also, there are modules for detecting deviations and anomalies, such as thresholds and peaks. Furthermore, the module library offers buffering, state, and other essential functions to ensure data delivery, quality and security.

These modules are combined to ensure that the solution continually delivers relevant data for energy consumption control and power monitoring. Read more

Why Moxa

Reliable connectivity is key in any energy monitoring project. Moxa’s networking, connectivity and its IIoT gateway and edge computing portfolio gives installers and maintainers of power systems worldwide the reliable hardware platform they need to run Crosser safely for 5, 10, or more years.

Andrea Magnago

Director of International Sales

Kai Schwab

Director DACH

Marco Novarese

Key Account Manager

Featured Resources

Related Products

Find out how our edge-to-cloud connectivity solutions make the IIoT work for you